|

品牌: 威尔

产品规格: 圆度测量仪

圆度仪是以精密回转中心为回转基准,通过传感器测量工件不同转角位置上的实际轮廓到回转中心的半径变化量,来定量评价被测件某一横截面圆度的测量仪器。可用于测量内,外回转表面各截面轮廓的圆度,同心度和端面跳动等参数。

Roundness measuring instrument is benchmark against precision rotary center, the quantitative evaluation of the cross-section roundness is made by measuring the radius varitation of actual contour of workpiece in different angle position to rotary center by sensor. It is used to measure the cross-section roundness and coaxiality of internal rotation and external rotation and face runout, etc.

评价项目: 圆度、同心度、平面度、径向单跳动

分析能力:

频谱分析、缺口/毛刺自动剔除、波形分析

圆度评定方式(4种): 最小区域法、最小二乘法、最小外接圆法、最大内切圆

圆度滤波档位:1-15upr,1-50upr,1-150upr,1-250upr,1-500upr,15-100upr,15-500upr,2-15upr

滤波形式: 高斯(ISO标准)

Evaluation item: Roundness, concentricity, flatness,Single radial runout

Analytical ability:

Spectrum analysis, gap/burr automatically removed, waveform analysis

Roundness evaluation (4 methods): Minimum zone method, least square, minimum circum circle and maximum inscribed circle

Roundness filtering gear: 1-15upr,1-50upr,1-150upr,1-250upr,1-500upr,15-100upr,15-500upr,2-15upr

Filtering expression: Gaussian (ISO standard)

项目 Item 参数 Parameter 旋转工作台 Rotary table 旋转精度 Rotation accuracy (0.025+6H/10000)μm 气浮轴系 Gas bearing 旋转速度 Gas bearing 6rpm 工作台有效直径 Adjust table diameter 180mm 最大工件直径(回转直径) Rotation diameter 420mm 最大测量直径 Max measure diameter 250mm 台面最大承重 Table loading capacity 10Kg 垂直轴(Z轴) Column (Z-axis ) 垂直移动 Vertical travel 320mm 垂直移动方式 Vertical movement mode 电动 Electric 最大检测高度(离旋转工作台) Maximum detection height 320mm 最大检测深度 Max detection depth 100mm(最小内径:30mm) 100mm (min inner diameter) 水平臂(X轴) horizontal arm (X-axis) 水平移动 Horizontal travel 100mm 突出量 Protrusion amount 25mm 水平移动方式 Horizontal movement mode 手动 Manual 检测器 Detector 采集器件 Acquisition device 圆光栅 Circle grating 圆周采样点数 Circumference of sampling 4096点 Sensor type 电感传感器 Inductive Sensor 传感器量程 Sensor range ±300μm 传感器分辨率 Sensor resolution 最高 0.001μm Max 0.001μm

技术特点 Technical characteristics

① 采用气浮主轴,精度保持更持久,稳定性好。Adopt gas spindle: Maintain long-term accuracy, good stability.

② 关键件采用特殊去应力合金材料及特殊的去应力处理工艺,精度保持长久。Key components use special de-stress alloy and special de-stress processing procedure to keep accuracy.

③ 模块化设计使用户维护成本降至最低。Modular design save user’s maintenance cost to the lowest.

④ 强大的消偏心功能,方便用户快速测量、同类工件的测量做到即放即测无需调整。

Eliminate eccentric function make it easy for users to measure quickly. The similar measurement of the same kind work piece can be measured immediately without the need to adjust.

⑤软件自主研发,模块化设计使用户维护成本降至最低。Self-developed software, module design decrease which decrease the users maintenance cost;

⑥软件辅助调心调平,提高效率,节省时间。Software aided self-aligning leveling, improve efficiency and save time.

⑦软件支持中文、英文,且支持XP、win7、win8系统。Software support XP、win7、win8 system, Chinese and English language.

⑧标准报表设有各种评定方式,测试报告栏中参数可根据需要进行添加和删除。Standard report is equipped with a variety of evaluation method, the parameters in column test report can be add or delete according to the users requirement.

⑨测量结果可选择ISO统计报表或ISO标准报表。Measurement results can choose ISO statistics or ISO standard reports

⑩可选配换向器模块。Commutator module for optional.

|

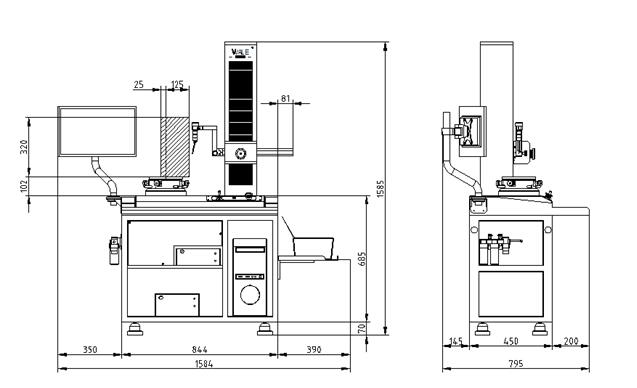

外形尺寸(mm) Overall Dimension |

主机重量 (Kg) Machine Weight | ||

|

Lx |

Ly |

Lz | |

|

1584 |

795 |

1585 |

320 |

环境要求 Environment Specifications

振源:无大振源

电源:AC 220V±10% 50Hz 单独地线

温度:现场温度:12℃—26℃ 理想温度20±2℃

相对湿度:<85%

气源:空压机气源压力:0.5-0.8Mpa

空压机气源流量:≧0.2m³/min

仪器入口空气压力露点≤10℃

油雾浓度≤0.5mg/m³、固态物≤3um

固态颗粒含量:≤5mg/m³

Vibration source:Without vibration source

Power:AC 220V±10% 50Hz Separate ground

Temperature:in site temperature:12℃—26℃ ideal temperature 20±2℃

Relate humidity:<85%

Air supply:Air compressor air pressure:0.5-0.8Mpa

Air compressor air flow:≧0.2m³/min

Air pressure dew point at instrument inlet ≤10℃

Oil mist detector ≤0.5mg/m³,SOLID ≤3um

Content of solid particles ≤5mg/m³

设备配置 Equipment configuration

| 部件名称 | 项目名称 | 数量 | 备注 |

| Part Name | project name | Quantity | Remarks |

| 主机部分 | 基础工作台 | 1套 | |

| Host part | Basic workbench | ||

| 高精度气浮主轴 | 1套 | ||

| Gas bearing | |||

| 立柱系统 | 1套 | ||

| Column | |||

| 横向系统 | 1套 | ||

| Transverse rail | |||

| 精密调心调平工作台 | 1套 | 调心:±3mm 调平:±2° | |

| Adjustment table | center adjustment:±3mm | ||

| Horizontal Adjustment :±2° | |||

| 数据采集及处理系统 | 1套 | ||

| Data acquisition and control | |||

| 计算机部分 | 电脑 | 1套 | |

| Computer | Computer | ||

| 打印机 | 1套 | HP | |

| Printer | |||

| 软件 | 1套 | ||

| Measurement software | |||

| 配件 | 测针 | 1支 | Φ2*10mm Renishaw 红宝石 |

| Accessories | stylus | ||

| 传感器 | 1套 | ||

| Sensor | |||

| 精密三爪卡盘 | 1套 | 3号千岛卡盘 | |

| Three jaw chuck | |||

| 工具箱 | 1套 | ||

| Toolbox | |||

| 精密除油雾调压装置 | 1套 | 进口SMC | |

| Oil mist removal equipment | |||

| 定标块 | 1个 | 缺口标准件 | |

| Standard parts |

售后服务 After-sale service

质保期:从安装验收合格之日起12个月,但不超过发货之日起15个月。在此期限内因我方原因造成的机器故障,负责免费维修。

质保期外:我公司采取定期回访与随时电话咨询相结合的售后服务制度,力求及时发现并解决用户使用中存在的困难和问题,为用户提供技术咨询。

公司负责为用户免费提供计量测试技术咨询服务。

公司以成本价终身为用户提供设备保修服务。

如公司接到用户设备故障请求服务电话,24小时响应,如有必要72小时内派技术人员赴现场解决问题。

公司备有备品备件库,终身负责为用户以成本价提供备品备件服务。

公司负责以优惠价终身为用户提供技术升级、改造等售后增值服务。

用户所在地区如有我公司地区办事处,其售后技术服务事宜由我公司地区办事处全面负责。

Warranty Period: Within 12 months from the date of acceptance, but not exceeding 15 months from the date of shipment.

During this period machine failure caused by our side should be maintained free of charge.

Extra Warranty Period: we will take telephone and regular visit to users as after-sale advisory service.

Our company is responsible for the technical advisory services of metrology for user free of charge.

We will provide life warranty services of machine for users with cost price.

If we get telephone service request about equipment failure from users, we will response to the request in 24 hours,

if necessary we will send technical engineer to the customer’s site to solve problems within 72 hours.

We have spare parts in stock, will provide life warranty services of spare parts for users with cost price

We will provide users with lifelong after-sales value-added technical service,such as technical upgrades,retrofit,etc.by preferential prices.

If there is my company’s office in the region of the users, it will fully responsible for the after-sale technical services.