|

产品规格:粗糙度仪,轮廓测量仪

本仪器测量原理为直角坐标测量法,即通过X轴、Z1轴传感器,测绘出被测零件的表面轮廓的坐标点,通过电器组件,将传感器所测量的坐标点数据传输到上位PC机,软件对所采集的原始坐标数据进行数学运算处理,标注所需的工程测量项目。

The measuring principle of this instrument is the rectangular coordinate measuring method,through X-axis, Z-axis sensor, mapping the surface contour coordinates point of the part under test,data transmission the coordinates point to the upper PC by electrical components.To do the mathematical treatment on the original collected coordinate data by software, marked with the required engineering survey projects.

测量功能 Measuring function

1、轮廓测量功能

尺寸:包含水平距离、垂直距离、线性距离、半径、直径

夹角:包含水平角、垂直角、夹角

位置公差:包含平行度、垂直度

形状公差:包含直线度、凸度、圆弧轮廓度

辅助生成:包含辅助点、辅助线、辅助圆

Size: contains the horizontal distance, vertical distance, linear distance, radius and diameter

Angle: horizontal Angle and vertical Angle, Angle

Position tolerance: contains the parallelism and perpendicularity

Shape tolerance: contains the straightness, crown, circular arc profile

Auxiliary generation: contains the auxiliary point, auxiliary line, auxiliary circle

2、粗糙度测量功能

测量参数Measure items: Ra、Rt、Rp、Rz(jis)、Rz(DIN)、Rz、Rvk、Rv、R3z、Rs、Rsm、Rc、Rsk、Rk、Rmax、Rpk、Mr1、Mr2、Rq、Rku、R△q

|

项目 Item |

参数 Parameter | |

|

X轴 |

测量范围 Measuring range |

120mm |

|

检测方法 Detection method |

新型数字式传感器/分辨率:0.2μm New digital sensor Resolution:0.2μm | |

|

测量速度 Measurement Speed |

0.1,0.2,0.5,1mm/s 自定义 | |

|

驱动方式及速度 Drive mode and Speed |

电动 4档,可自定义速度 Electric ,4 gear,can customize speed | |

|

直线度 Straightness |

1.2μm/100mm | |

|

线性精度 Linear accuracy |

±(1.5+0.025L)μm | |

|

Z1轴/轮廓部分 |

量程 Sensor range |

24mm |

|

线性精度 Linear accuracy |

±(1.2+|0.04H|)μm | |

|

检测方法 Detection method |

新型数字式传感器/分辨率:0.01μm New digital sensor Resolution:0.01μm | |

|

水平精度 |

±(1+0.025L)μm | |

|

垂直精度 |

±(0.8+|0.03H|)μm | |

|

Z1轴/粗糙度部分 |

传感器量程范围 Sensor range |

800μm/80μm |

|

分辨率 Resolution |

12nm(800μm量程时) 1.2nm(80μm量程时) | |

|

截止波长 Cut-off wavelength |

0.025、0.08、0.25、0.8、2.5、8mm | |

|

测量重复性 Repeatability |

±3% | |

|

线性精度 Linear accuracy |

±5% | |

|

评定长度 Evaluation length |

λc×3、4、5、6、7 | |

|

Z轴 |

立柱行程 Column travel |

400mm |

|

驱动方式及速度 Drive mode and Speed |

电动 4档,可自定义速度 Electric ,4 gear,can customize speed | |

技术特点 Technical characteristics

① X、Z1均采用新型数字式传感器,精度更高

② 大量程设计,杠杆比仅为1:2.2,最大限度保持了传感器的原有精度

③ 高刚性高精度直线运动导轨、高精度数字式线性传感器

④ 采用高速并行数据采集单元,硬件触发、硬件高速采样,无延时;足够密集及稳定的数据源为后期数据处理、计算提供最有力的保障

⑤ 更换传感器部分即可实现粗糙度测量。

① X, Z1 adopt imported new digital sensor, higer precision ;

② Design in a wide range, leverage ratio is 1:2. 2, the maximum keep the original precision of the sensor;

③ High rigidity, high precision linear motion guide rail, high precision digital linear sensor;

④ Using high speed parallel data acquisition unit, high-speed sampling hardware trigger, hardware, without delay. Dense and stable source provide the most powerful guarantee for later data processing, calculation.

⑤ Roughness measurement can be achieved by changing the sensor part.

轮廓测量软件系统 Software System

强大的系统功能

软件兼容winXP、win7、win8系统 Software support XP、win7、win8 system.

软件支持中英文 Software support Chinese and English language.

快捷自由的页面布局

软件增设快捷键,方便使用 Software add shortcuts, easy to use

支持将菜单及控制区收起操作,以扩大绘图区的有效区域面积 Support pack up the menu and control operation, to enlarge the drawing effective area

丰富的数据处理系统

圆弧、线自动识别 Automatic identification of circular arc, the line

拟合可选择点选或框选 Fitting choice click or marquee

软件标注与CAD同理 Software similarly marked with CAD

支持连续标注、基准标注、支持任意插入点 Support continuous annotation and datum mark, support any insertion point

支持图形自由旋转及坐标自由旋转 Support the freedom of graphic rotation and coordinate rotation

支持坐标点标注 Support the coordinate points label

捕捉开关打开时,自动生成及捕捉交点、圆心 、线段中点、端点、圆弧交点、中点、切点等特征点

While capture switch is opened, automatically generated and capture the intersection point, circle, line midpoint, endpoint, circular intersection, midpoint, point of tangency feature points, etc

完善的数据保存模式

原始数据自动保存,便于多次标注 Original data automatically saved, facilitate multiple labels

可将测量的图形结果转化成DXF格式 Measurement graphic results can be transferred into DXF forma

镜像功能,可保存标注后文件 The mirror function, can save after standard file.

便捷的控制方式

可对Z1、X轴当前位置进行监控 Can monitor the current position of the Z1, X axis

测量长度可任意设定 Measuring length can be set freely.

具有测针自动接触、自动抬起、自动回退功能 Needle automatic contact, automatic lift, automatic back.

可以对操作进行无限次的撤销及恢复操作 The operation can be unlimited undo and restore

SP2000最具特色的功能

非比例放大:即使在非比例放大的情况下,也能进行正常的角度、圆弧、水平、垂直、线性等标注。

自动标注:在进行批量测量时,首次测量保存为模板,再次测量导入模板即可完成自动标注,大大提高测量效率。

数据合成:对于类似直槽工件无法一次测量完成,通过摆放角度进行两次测量,然后通过软件进行数据合成。

间断测量:可对工件进行分段编程(采样间隔、采样速度),提高客户测量效率。

粗糙度测量软件 Roughness Software System

特色数据再处理功能:当实际测量部分与需要被测量部分有差时,可框选出需要进行数据处理部分的粗糙度曲线,将该部分曲线截取出来重新处理分析。Data reprocessing: After the measurement is completed, you can select the data processing part of the measurement curve to reprocess the analysis.

测量图形不仅可等比放大,且可单轴非比例放大。Measurement graphics can not only be magnified, but also uniaxial non-proportional amplification.

测量报告分为当前报告及统计报告,统计报告可用于分析同个工件重复测量数据及同批量工件的测量数据,便于用户直观看出数据的变化。The measurement report is divided into the current report and the statistical report, and the statistical report can be used to analyze the repeated measurement data of the same workpiece and the measurement data of the same batch of workpieces, so that users can see the change of the data intuitively.

环境要求 Environment Specifications

电 源:AC 220V±5% 50Hz 单独地线

功率需求:约500W

环境要求:现场温度:15~25℃、理想温度:20±2℃

相对湿度:<85%

室内周围应无影响测量的灰尘、振动、噪音、气流、腐蚀性气体和较强磁场

Power supply: AC 220 v + 5% for 50 hz Seperate groud wire

Power requirements: about 500 w.

Environmental requirements: the temperature: 15 ~ 25 ℃, ideal temperature: 20 + 2 ℃

relative humidity: < 85%

Around the indoor should have no affect the measurement of dust, vibration, noise, air, corrosive gas and strong magnetic field.

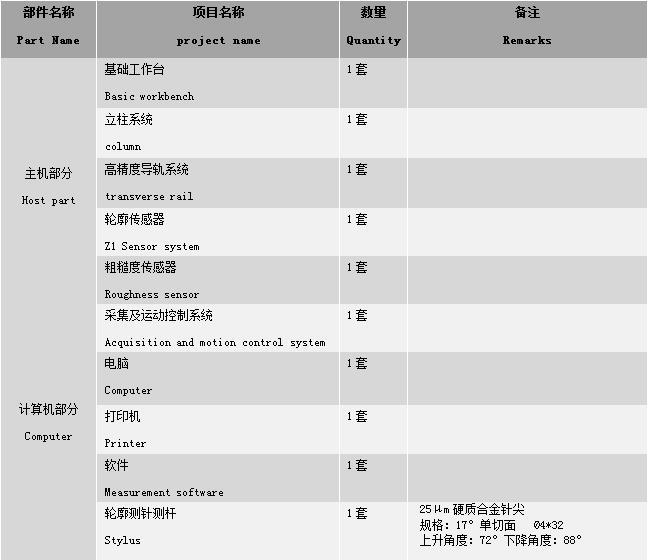

设备配置 Equipment configuration

售后服务 After-sale service

Extra Warranty Period: we will take telephone and regular visit to users as after-sale advisory service.

Our company is responsible for the technical advisory services of metrology for user free of charge.

We will provide life warranty services of machine for users with cost price.

If we get telephone service request about equipment failure from users, we will response to the request in 24 hours,

We have spare parts in stock, will provide life warranty services of spare parts for users with cost price

We will provide users with lifelong after-sales value-added technical service,such as technical upgrades,retrofit,etc.by preferential prices.

If there is my company’s office in the region of the users, it will fully responsible for the after-sale technical services.